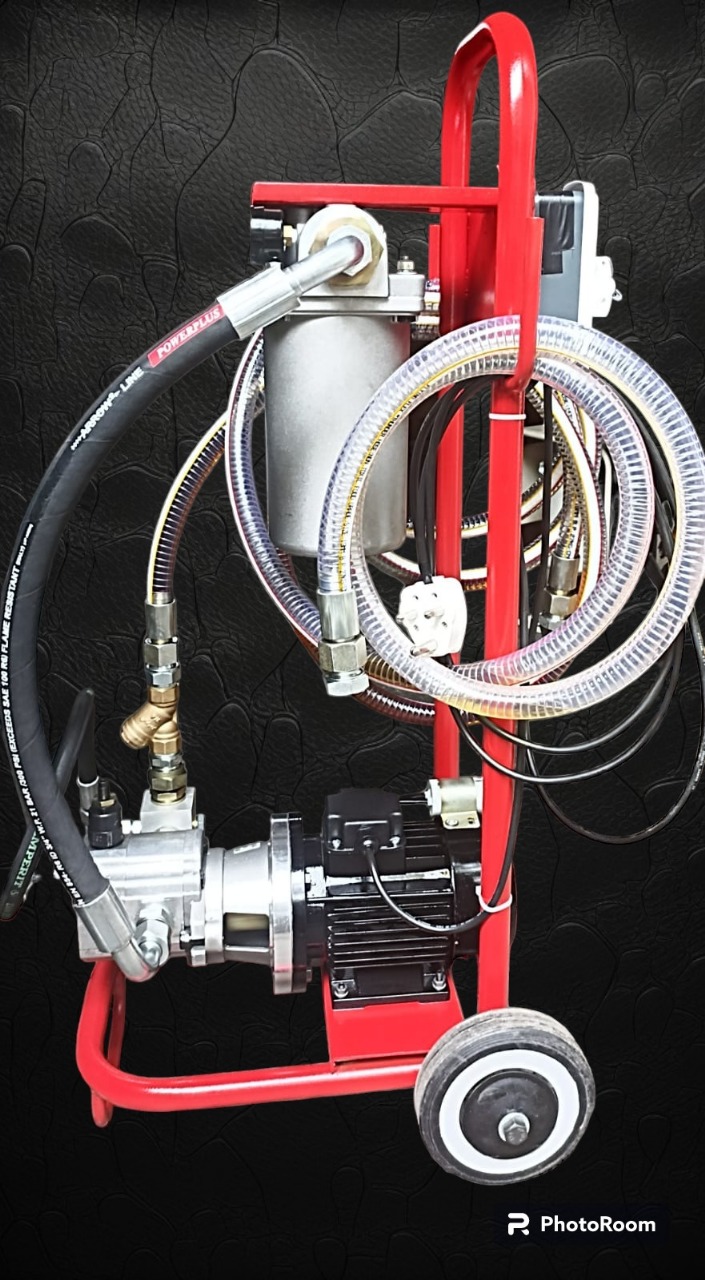

Hydraulic oil filtration machines play a very important role in keeping hydraulic systems clean and working smoothly. These machines remove dirt, water, and other impurities from hydraulic oil, helping to improve the life of the machinery and reduce breakdowns. At Ace Hydraulic Controls And Systems, we understand the importance of regular maintenance to get the best performance from your equipment.

In this blog, we will share some useful and practical maintenance tips to help you take good care of your hydraulic oil filtration machines. Whether you are using them in a factory, workshop, or construction site, these tips will help you save time, money, and effort in the long run.

Lets see, Tips for Maintaining Your Hydraulic Machinery

The first and most important step is to follow a regular maintenance schedule. Just like how we take our vehicles for servicing, filtration machines also need regular checks. Depending on how frequently you use the machine, plan monthly or quarterly inspections.

At Ace Hydraulic Controls And Systems, we always suggest creating a maintenance logbook. This helps to keep track of when each part was last serviced or replaced.

Filter elements are the heart of your hydraulic oil filtration machine. They trap the contaminants and keep the oil clean. Over time, these filters get clogged and lose their efficiency.

Tips:We at Ace Hydraulic Controls And Systems use high-quality filter elements to ensure longer life and better filtration results.

Leaks can happen if the hoses or fittings become loose, cracked, or worn out. Oil leaks not only waste oil but also create safety hazards.

What to check:Dirt and dust can enter the filtration system from the outside if not cleaned regularly. Keeping your machine clean improves its life and efficiency.

Simple cleaning tips:TA clean machine is a healthy machine. It also helps in identifying small issues before they become big problems.

The main job of the filtration machine is to clean hydraulic oil. But if the oil quality is already too bad (for example, mixed with too much water or sludge), the filtration machine may not work effectively.

What to do:Ace Hydraulic Controls And Systems also offers oil analysis services to help customers decide the best course of action.

The motor and pump are the driving force behind the filtration system. They should be checked regularly for smooth operation.

Check for:If you find any issues, don’t delay in calling a service expert. Regular lubrication and alignment checks can avoid costly repairs.

If the filtration machine is not used every day, proper storage is necessary.

Storage tips:At Ace Hydraulic Controls And Systems, we design compact and easy-to-store machines that are ideal for Indian industries.

Proper maintenance of hydraulic oil filtration machines is essential to protect your valuable equipment and maintain productivity. A small effort today can prevent major failures tomorrow.

At Ace Hydraulic Controls and Systems , we not only manufacture reliable filtration machines but also provide full support for maintenance and servicing. Our team is always ready to guide you with the right advice, genuine spare parts, and on-site service if needed.

If you have any questions about maintaining your hydraulic filtration system or need service support, feel free to contact us. Let us help you keep your machines in top condition.